|

The motor controller is the device which controls the flow of power from the batteries to the motor, allowing you to vary the speed and acceleration of the vehicle. Many years ago motor controllers consisted of contactors and/or resistor networks, but all modern motor controllers are based on transistors amplifiers controlled by microprocessors.

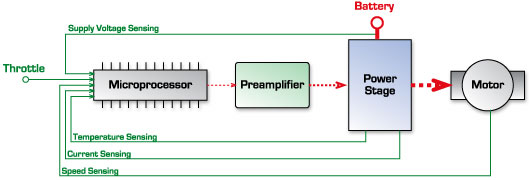

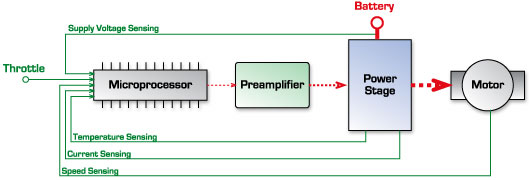

Topology of a Modern Motor Speed Controller

The diagram below shows a typical topology for a motor speedcontroller. They

use a microprocessor to drive a preamplifier and then power stage amplifier

which controls the flow of power from the battery to the motor, with various

feedback sensors to monitor the system's operation. Red arrows indicate pulse

width modulated outputs, green indicates feedback sensors.

What is Pulse Width Modulation?

|

All modern motor controllers use some form of Pulse Width Modulation

(PWM) to vary the amount of power being delivered to the motor

from the power source (e.g batteries).

PWM is the process of switching the connection between the source

and load very rapidly to simulate a lower average voltage. The

frequency of switching is usually around 20 000 times per second

(20kHz) to keep it outside the human hearing range.

(Due to the inductive nature of the motor, most controllers effectively

behave somewhat like a buck converters – for more information,

check out wikipedia's

entry on buck converters.)

|

|

|

Microprocessor and Sensors

|

The microprocessor's primary responsibility is generating

an appropriate PWM signal for the power electronics based on the

status of the various sensors. Some controllers will use dual

microprocessors for safety (so if either processors fault, the

system will shut down gracefully). As well as the throttle input,

most controllers should support the following sensors:

- Voltage: Too high a supply voltage can damage the motor

and/or power stage. Too low a supply voltage can mean the

batteries are over-discharged, which can cause them irreversible

damage.

- Current: Most controllers will include a variable current

limit to protect components.

- Temperature: To avoid damage to the power stage due

to thermal overload. Some controllers may also support thermal

sensors on the motor.

- Speed: Useful for detection of stall conditions or

overspeed, which can both damage the motor. Can also be used

for cruise control on some controllers.

|

Power Stage

The heart of the power stage is a bank of transistor amplifiers

– usually either MOSFETs or IGBTs.

- MOSFET stands for Metal Oxide Semiconductor Field Effect Transistor.

These are more common among lower voltage controllers since

low voltage MOSFETs tend to have very low on resistance (and

hence power loss). MOSFET controllers are very efficient at

low power levels, since power loss in a MOSFET is proportional

to the square of the current. Their resistance also increases

as they heat up, so when used in parallel they tend to automatically

balance the load.

- IGBT stands for Insulated Gate Bipolar Transistor, and it

somewhat like a hybrid between bipolar transistors and field

effect transistors. IGBTs have a constant voltage drop which

makes them more efficient than MOSFETs at high power levels,

though often less efficient for low power applications. One

disadvantage with IGBTs is that, like all bipolar transistors,

they are prone to thermal runaway and imbalances when used

in parallel. As such IGBT controllers require good cooling

systems (liquid cooling is common) and/or matched transistors

to avoid imbalance.

|  |

Major manufacturers

- Curtis Instruments make

a range of DC motor speed controllers with power ranging up to 144V 500A

(72kW). The Curtis 1231C is probably the most commonly used controller

in EVs around the world.

- Cafe Electric make controllers ranging from 156V 1000A (156kW) to

350V 2000A (700kW!), CafeElectric Zillas are a popular choice for many

high performance EVs using series DC motors.

- Siemens are the main supplier of

controllers (and motors) for AC induction drive systems. AC equipment is still kind of

pricey at present.

- ZEVA currently produces an ecomonical 144V 600A (86kW) series DC motor speed

controller for use in small road-going cars.

Curtis 1231C

|

Cafe Electric Zilla2K

|

Siemens Simotion

|

ZEVA MC600S

|

|